Soldering Technology

Plants and systems for void-free soldering with vacuum

Vacuum soldering for high-quality production

The power density of advanced electronic components like e.g. power modules, hybrid and multichip components, etc. is continuously growing. Therefore, the quality of solder connections must fulfill the increasing demands as well. Gas inclusions (= voids) in the solder connections must be avoided.

The best way to remove such from the liquid solder is the systematic use of vacuum during the soldering process.

The vacuum soldering systems by PINK provide void-free solder connections, e.g. of large power modules, with preform solders and / or pastes in a continuous process.

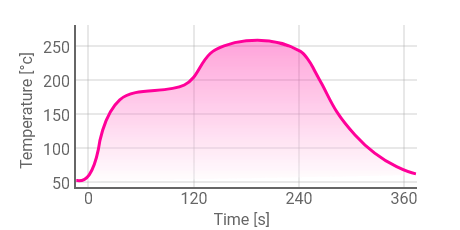

Typical soldering profile for lead-free solders

Advantages of the VADUs

- Short cycle times and high performance by intelligent temperature management

- Environment-friendly and easy to operate due to a smart design

- Flexible soldering technologies for individual customer demands

- Perfect and reproducible soldering results due to a continuous process control

Void quantity

after chip soldering without vacuum process

after chip soldering with vacuum process

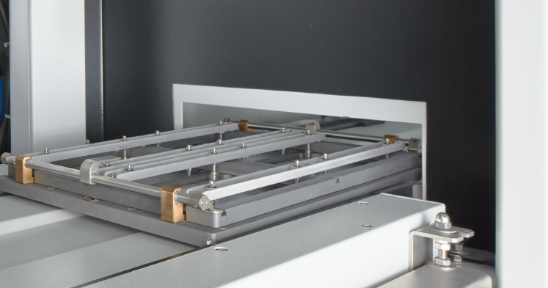

Vacuum soldering systems

PINK offers soldering systems suitable for each production strategy: VADU 100 for laboratory or batch production, VADU 200XL for batch operation or VADU 300XL and VADU 400XL as automated inline systems for series production.

- Batch system

- 1 chamber

- Clearance height max. 50 mm

- Dimensions: 1,070 x 1,130 x 1,150 mm

- Batch system

- 2 chambers

- Clearance height max. 100 mm

- Dimensions: 1,200 x 1,890 x 1,680 mm

- Batch system

- 1 chamber

- Clearance height max. 50 mm

- Dimensions: 1,330 x 1,180 x 1,200 mm

- Inline system

- 3 or 4 chambers

- Clearance height max. 100 mm

- Inline system

- 2 - 5 chambers

- Clearance height max. 100 mm