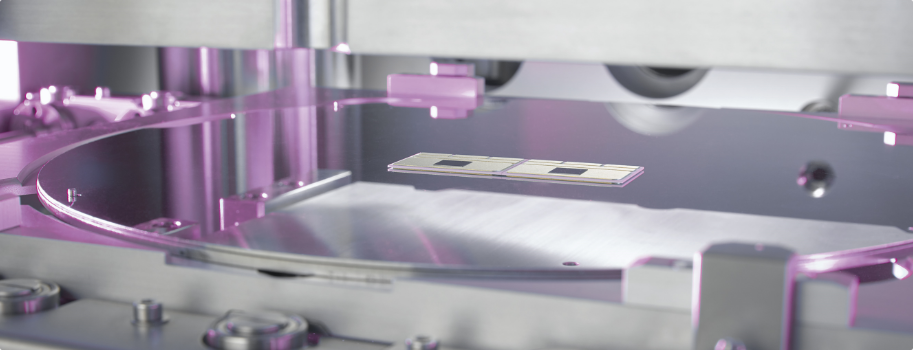

Vacuum assisted, small scale

sintering system SIN 20

For R&D and small series production

The new sinter equipment SIN 20 is developed to support R&D and institutes in setup, evaluation and optimization of sintering processes.

The SIN 20 is using PINK’s well known, approved and patented equilibrates-vacuumtechnology, based on the technical principle of pressure equalization. This allows sintering in perfect N2 atmosphere as well as in reductive atmosphere like formic acid. Cu substrates as well as substrates with an Au or Ag finish can be sintered.

- Flexible top tooling system (high force Softtool or Hardtool)

- Target applications:

– Die attach on substrate and lead frame

– Attach of substrate to baseplate

– Die top interconnect

– High power LED attach

SIN 20

Equipment specifications

- Hermetic sealed process chamber

- Process area:

– Sintering: up to 100 x 100 mm

– Max. product height: 50 mm

– Min. distance between products: 0 mm - Heating system:

– Heating plate temperature up to 350 °C

– Separate cooling and heating zone - Top tool system:

– Dynamic adaptable pressing force from 1 kN up to 200 kN

– Continuous force: 175 kN

– Dynamic adaptable pressure up to 30 MPa with Softtool and up to 60 MPa with Hardtool

– Dynamic controlled and monitored pressure ramps

– Drive speed: upwards up to 17.5 mm/s, downwards up to 27.5 mm/s - Atmosphere Control System:

– Exact control of inherent gas atmosphere (N2, N2/O2, N2/H2, HCOOH)

– Atmospheric pressure range: 1 - 960 mbar - Process Control and User Interface:

– Freely programmable controlled and monitored temperature, atmospheric pressure and pressure profiles

– Permanent process control - Connectivity:

– Ethernet interface

– Remote maintenance (VPN) - Low energy and process media consumption