Application and R&D services for soldering and sintering technology

Within a rapidly increasing and competitive market, fast process developments with highest yield and reliability are needed to satisfy the ever-growing demands for modern electronic devices.

With its application and R&D services PINK supports its customers from the very beginning of packaging development to series production. Starting with equipment demonstrations, soldering and sintering trials, PINK provides feasibility studies of new packaging concepts incl. package assembly.

PINK also evaluates and improves UPH, yield and quality. Essential process knowhow is given to the customer‘s engineers and technicians by trainings. In case of process issues PINK offers continuous support.

Range of services

- Consulting and concept development

- Trials and demonstrations for customers

- Feasibility studies

- Prototype assembly

- Process development

- Process training and support

Applications for soldering/sintering

- Die-attach

- Substrate to baseplate

- Die top side connection

- Double-sided packaging

- Leadframe connection

- Multi-layer packaging

PINK equipment

- VADU soldering systems

- Sintering system SIN 20 and SIN 200+

- Plasma cleaning equipments

- Circulating air oven

Additional equipment

- Pick & place machine

- Stencil printer

Test devices

- Test DBCs with Au, Ag, Cu metallization

- Dummy Si chips

- AMB with Cu metallization

In-house quality inspection

- SAM analysis

- Shear and peel testing

- Microscopy

- Mandrel bending test

- Surface tension measurement

- IR camera

External analysis

- X-Ray

- Cross sectioning

- REM/EDX analysis

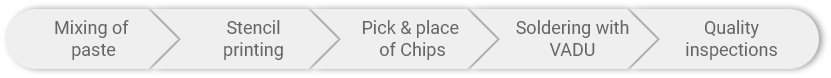

Example of a sinter process with paste

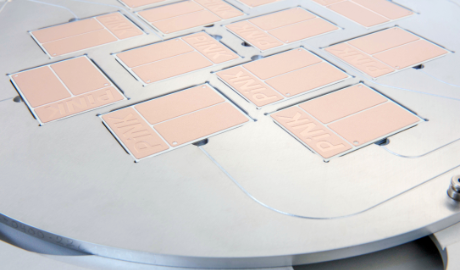

Sintering carrier with single substrates

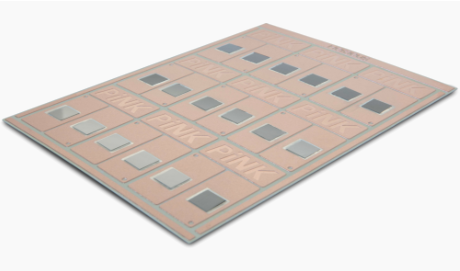

Test layout for soldering tests

August 2018: Opening of the application and training centre of PINK GmbH Thermosysteme