Vacuum circulating air ovens VUT

Reliable drying with a combination of vacuum and circulating air

To vacuum-dry a product that is embedded in a product carrier or, due to its inherent structure, exhibits poor heat transfer by conduction, it makes good sense to combine two different forms of drying: vacuum and circulating air.

For such applications, PINK has its VUT vacuum circulating air oven. The product is heated to a defined temperature by circulating air, then a vacuum is generated. This process runs alternately, the number of cycles depends on the product's drying behaviour.

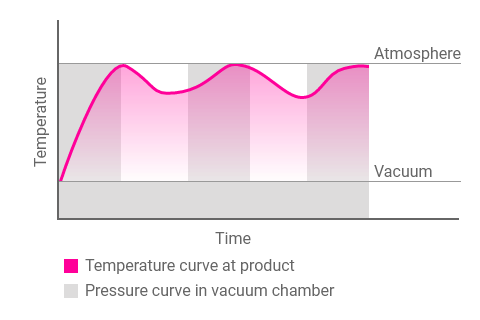

Diagram for combined vacuum circulating air operation

The vacuum circulating air cycle can be repeated several times as required

Vacuum circulating air ovens VUT

Vacuum circulating air system with specially positioned air baffles for a defined air flow

Inline system with circulating air heating zones and a vacuum drying zone

Compare Drying systems / Isolators

|

Type |

VT | UT | VUT |

| Type of system | Vacuum drying oven | Circulating air oven | Vacuum circulating air oven |

| Drying principle | Vacuum, heat | Circulating air, heat | Vacuum, circulating air, heat |

| Shelf area1 | 1 to 20 m2 | 0.8 to 12 m2 | On request |

| Heating | Hot water, thermal oil, electric | Hot water, thermal oil, electric, steam | Hot water, thermal oil, electric |

| Temperature [°C] |

max. 200 | max. 250 | max. 200 |

| Materials | High-grade stainless steels | High-grade stainless steels | High-grade stainless steels |

| Surfaces | Ground and polished2 | Ground and polished, mill finish | Ground and polished, mill finish |

|

Options |

|||

| Charging trays (standard and pharmaceutical design) |  |

|

|

| Charging and support cart loading |  |

|

|

| Wall installation |  |

|

|

| Pass-through design with lock function |  |

|

|

| ATEX design |  |

|

|

| Automated loading and charging |  |

|

|

| Validable CIP | - | - | - |

1 Other sizes available on request, 2 Electropolished on request