Surface treatment

with low-pressure plasma

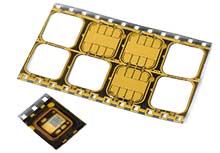

Plasma activation

The surface tension of polymer materials can be increased with the help of plasma activation. The activation enables subsequent processes such as painting, bonding, printing and sealing to be carried out without exposing the material to thermal stresses (cold plasma) and without aggressive primers.

Plasma cleaning

Plasma cleaning leaves surfaces completely free of organic contaminants. Because this is a dry chemical process carried out at room temperature, it is possible to pass on the cleaned parts immediately for further processing.

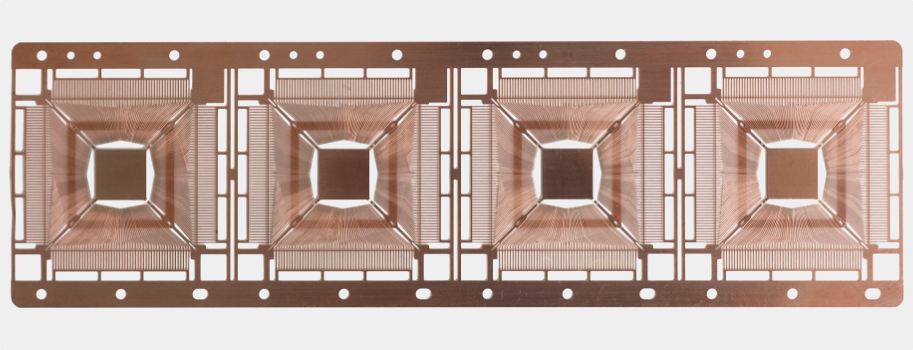

Plasma etching

Plasma etching (dry etching) is used to remove ("descum", "desmear", "back etch" etc.) production process materials such as photoresist and sacrificial layers. Thanks to the distinctive mobility of the plasma, even the finest of structures can be reached.

Plasma coating

With plasma coating (PECVD = plasma enhanced chemical vapour deposition), materials or workpieces are furnished with a thin functional layer by polymerising suitable precursors in plasma state.