Drying Technology

Gentle drying under vacuum

Among the thermal processes, vacuum drying has proven particularly effective in many sectors. The purpose of this process is to dry gently a high-grade product containing water or solvents without modifying the product characteristics.

During drying under vacuum, the total pressure in the drying oven is lowered so that the water or solvent vaporizes even at low temperatures.

The drying process is optimized by selectively controlling the heat supply and pressure.

A vacuum drying system basically consists of a drying oven with a heating system and a vacuum pump assembly, designed for a specific drying process with the associated control.

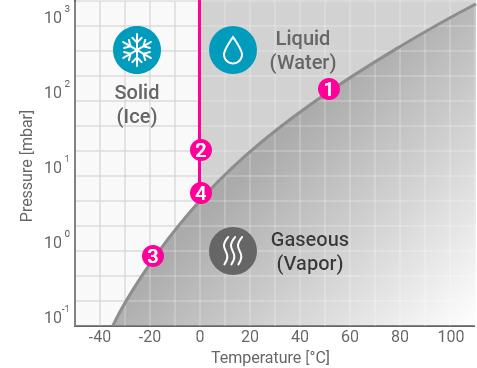

Phase diagram of water

- Condensation

- Melting

- Sublimation

- Triple point (0.01 °C/6.09 mbar)

Vacuum drying systems / Isolators

The right systems for drying and process technology: for laboratory (VSD-e) and standard drying processes (VT), for a GMP / FDA-compliant process (VSD), for the safe drying of HAPI products (VSDI) and for pre-filtering and drying liquid, toxic products (VSDIN).

- Vacuum drying oven

- Drying principle: Vacuum, heat

- Temperature: max. 200 °C

- Shelf area: 1 to 20 m2

- Heating: Hot water, thermal oil

- Materials: High-grade stainless steels, special materials such as Hastelloy, Inconel and titanium

- Surfaces: Ground and polished

- Vacuum drying oven with isolator

- Drying principle: Vacuum, heat

- Temperature: max. 200 °C

- Shelf area: 0.2 to 2 m2

- Heating: Hot water, thermal oil

- Materials: High-grade stainless steels, special materials such as Hastelloy, Inconel and titanium

- Surfaces: Ground and polished

- Vacuum drying oven with isolator and pressure nutsch

- Drying principle: Vacuum, heat

- Temperature: max. 200 °C

- Shelf area: 0.2 to 2 m2

- Heating: Hot water, thermal oil

- Materials: High-grade stainless steels, special materials such as Hastelloy, Inconel and titanium

- Surfaces: Ground and polished

- Vacuum drying oven

- Drying principle: Vacuum, heat

- Temperature: max. 200 °C

- Shelf area: 0.18 m2

- Heating: Electric

- Materials: High-grade stainless steels, special materials such as Hastelloy, Inconel and titanium

- Surfaces: Ground and polished

- Vacuum drying oven

- Drying principle: Vacuum, heat

- Temperature: max. 200 °C

- Shelf area: 1 to 20 m2

- Heating: Hot water, thermal oil, electric

- Materials: High-grade stainless steels

- Surfaces: Ground and polished

- Circulating air oven

- Drying principle: Circulating air, heat

- Temperature: max. 250 °C

- Interior volume: 0.8 to 12 m3

- Heating: Hot water, thermal oil, electric, steam

- Materials: High-grade stainless steels

- Surfaces: Ground and polished, mill finish

- Vacuum circulating air oven

- Drying principle: Vacuum, circulating air, heat

- Temperature: max. 200 °C

- Interior volume: On request

- Heating: Hot water, thermal oil, electric

- Materials: High-grade stainless steels

- Surfaces: Ground and polished, mill finish