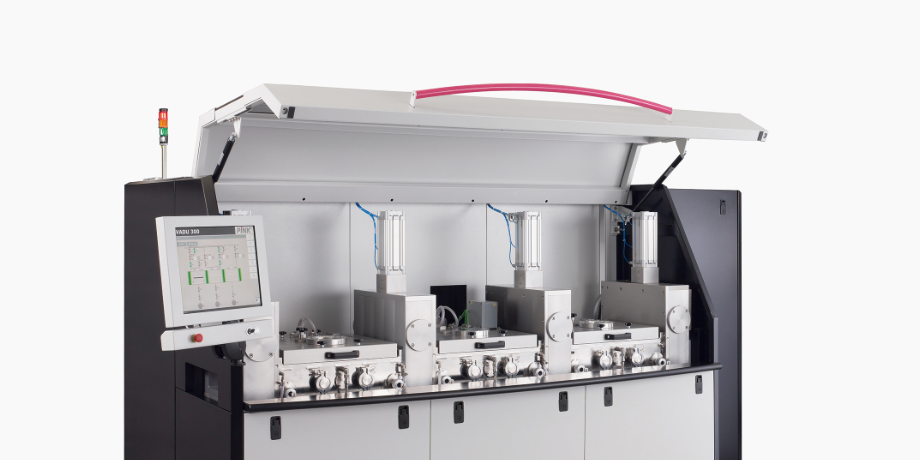

Vacuum soldering system VADU 300XL

Automated inline soldering system for series production

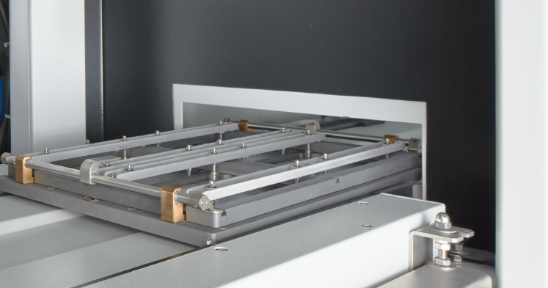

The soldering system VADU 300XL is equipped with three separate process chambers and internal substrate handling with inline carrier transfer for highly efficient series production. The system enables void-free solder connections with preforms and /or pastes in a continuous process. The reproducibility of the soldering processes is guaranteed by permanent process control.

The VADU 300XL can also be integrated in customer‘s automation processes. PINK develops solutions according to customer‘s requirements which range from the optimization of the carrier handling through surrounding transfer systems to connection with pick-and-place machines and robot automation.

Vacuum soldering system VADU 300XL

Data sheet

| Type of system | Inline system |

| Number of vacuum chambers | 3 chambers |

| Process area (W x D) | 410 x 280 mm |

| Clearance height | max. 100 mm |

| Vacuum (standard) | ≤ 2 mbar |

| Dimensions of the system (W x D x H) | 2,410 x 1,610 x 1,800 mm |

| Dimensions of pumping unit | 990 x 690 x 1,800 mm |

| Weight | 2,000 kg (without pumping unit) |

| Power supply | 3 x 400 V, 50/60 Hz |

| Power input | 25 kVA |

| SMEMA interface |  |

Options

| Alternative process areas (W x D) | 600 x 280 mm (XXL version) |

| Handling / transfer systems |  |

| Soldering temperatures up to 500 °C |  |

| Induction heating |  |

| Integrated MES interfaces (e.g. SECS/GEM) |  |

System features

- Void-free solder connections

- Soldering with preforms and / or pastes

- Individual soldering profiles

- Process temperatures up to 400 °C

- Controlled temperature gradients

- Short cycle times

- Separate soldering and cooling chamber

- Flux-free soldering with formic acid

- Flux management

- Inert gas atmosphere

- Residual oxygen content < 5 ppm

- Reproducibility of the soldering results

- Traceability

- Permanent process control

- Ethernet interface

- Remote maintenance (VPN)

- Low energy and media consumption

New modular VADU design

Explore the soldering system VADU 300XL with robot automation

Compare systems

|

Type |

VADU 100 | VADU 200XL | VADU 300XL | VADU 400XL |

| Type of system | Batch system | Batch or Inline system | Inline system | Inline system |

| Number of vacuum chambers | 1 chamber with 2 separate process zones |

2 chambers | 3 chambers | 4 chambers |

| Process area (W x D) [mm] |

168 x 280 | 410 x 280 | 410 x 280 | 410 x 280 |

| Clearance height [mm] |

max. 50 | max. 100 | max. 100 | max. 100 |

| Vacuum (standard) [mbar] |

≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 |

| Dimensions of the system (W x D x H) [mm] |

1,070 x 1,130 x 1,150 | 1,758 x 1,911 x 2,381 | 2,436 x 1,911 x 2,381 | 3,114 x 1,911 x 2,381 |

| Dimensions of pumping unit [mm] |

Integrated | 1,027 x 762 x 1,376 | 1,027 x 762 x 1,996 | 1,027 x 1,452 x 1,376 |

| Weight [kg] |

500 | 1,500 (without pumping unit) |

2,000 (without pumping unit) |

2,600 (without pumping unit) |

| Power supply | 3 x 400 V, 50/60 Hz | 3 x 400 V, 50/60 Hz | 3 x 400 V, 50/60 Hz | 3 x 400 V, 50/60 Hz |

| Power input [kVA] |

5 | 19 | 27 | 35 |

| SMEMA interface | – |  |

|

|

|

Options |

||||

| Handling / transfer systems |

|

|

|

|

| Soldering temperatures up to 500 °C |  |

|

|

|

| Induction heating |  |

- | - | - |

| Integrated MES interfaces (e.g. SECS/GEM) |  |

|

|

|