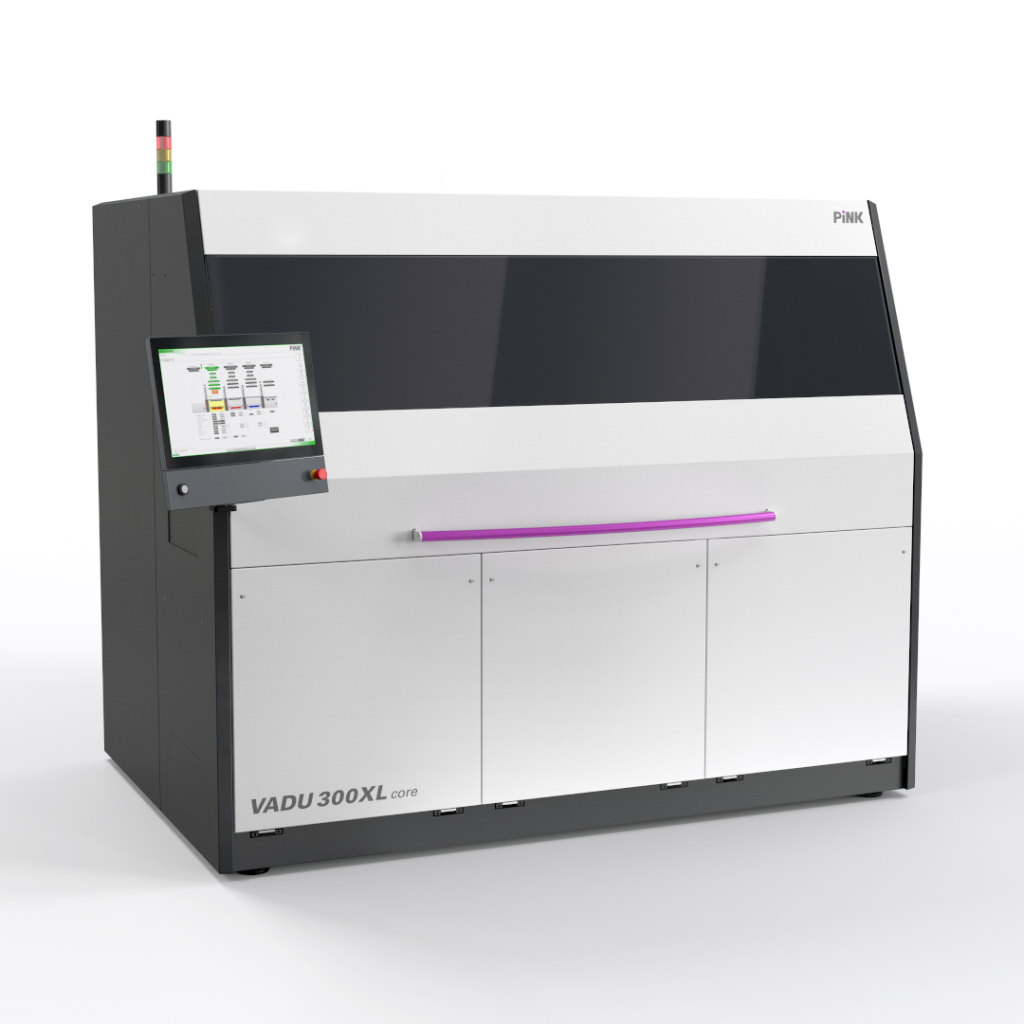

Products from PINK GmbH Thermosysteme

Our plants and systems are always manufactured according to individual customer requirements and completely in our factory in Wertheim / Germany. Our vacuum brazing systems, sintering systems, low-pressure plasma systems, drying ovens and insulators are used in all major markets around the world.

Our product areas

Products at a glance

VSD

- Vacuum drying oven

- Drying principle:

Vacuum, heat - Materials:

High-quality stainless steels, special materials such as Hastelloy, Inconel, titanium - Surface ground and polished

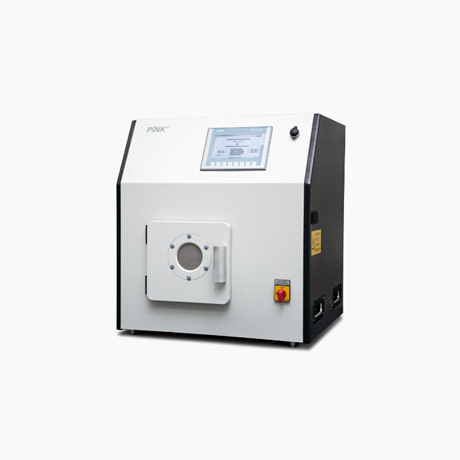

VSDI

- Vacuum drying oven with isolator

- Drying principle:

Vacuum, heat - Materials:

High-quality stainless steels, special materials such as Hastelloy, Inconel, titanium - Surface ground and polished

Contact us and let us work together to develop solutions that meet your requirements. We look forward to hearing from you and helping you further.